Project Name

Real-Time Field Monitoring and Loss Prevention

Customer

Under NDA

Industry

Agriculture

Country

Eastern Europe

Solution type

IoT Platform

Project Description

The challenge was to monitor raw material conditions in the field, collect sensor data, and track fleet and personnel locations. Another hurdle emerged when the emergence of spoilage hotspots during sugar beet storage, requiring timely detection and intervention.

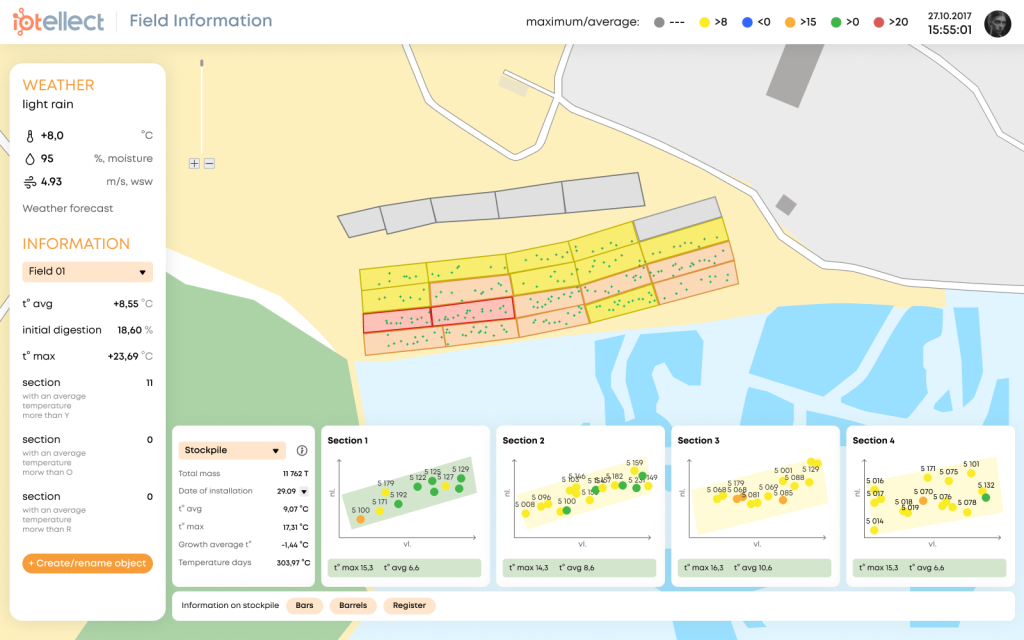

The Iotellect platform provided a real-time overview of all activity across the pile fields. Field sections and sensors were displayed as geo-fences on a layered map. This made it easy to scale and update in real time.

Color-coded indicators on the map showed temperature levels and sugar content percentages, enabling early identification of spoilage risks and effective response. As a result, the platform significantly reduced critical spoilage zones, optimized storage, and preserved raw material quality.

The system tracked failures and provided insights into root causes with visual maps and alerts via SMS or email. Customized notifications allowed automated monitoring of equipment issues and material degradation. Alerts were sent via the operator’s SMS gateway (SMPP protocol).

This automation reduced manual oversight and ensured rapid response to critical issues, helping maintain consistent quality and operational reliability.

Hardware and Environment

- The deployed measurement equipment supports non-standard communication protocols for connection with temperature, pres-sure, CO2, and GPS sensors.

Benefits

- Improved Machinery Performance. GPS vehicle tracking boosted coordination of heavy equipment, reducing idle time and streamlining field operations.

- Cut Raw Material Losses. Real-time monitoring of temperature, pressure, and CO2 levels reduced stock losses by 20%, minimizing spoilage risks.

- Maximized Production Output. Iotellect analytics helped extract more sugar from raw material, increasing yield and efficiency.

- Smarter Resource Allocation. Real-time tracking enabled better use of fleet and personnel, eliminating bottlenecks.

- Sustainable Operations. Continuous environmental monitoring supported eco-friendly practices and regulatory compliance.

Testimonials

With the Iotellect platform, we can now see everything happening in our operation as it happens. We catch potential spoilage problems early and coordinate our equipment much more smoothly, which has really cut down on waste and made our whole operation more efficient. This technology has become essential to our modernization efforts.

Client Representative