Project Name

Predictive Maintenance Reinvented for Hydropower

Customer

Under NDA

Industry

Power Engineering

Country

Under NDA

Solution type

Industrial Automation

Project Description

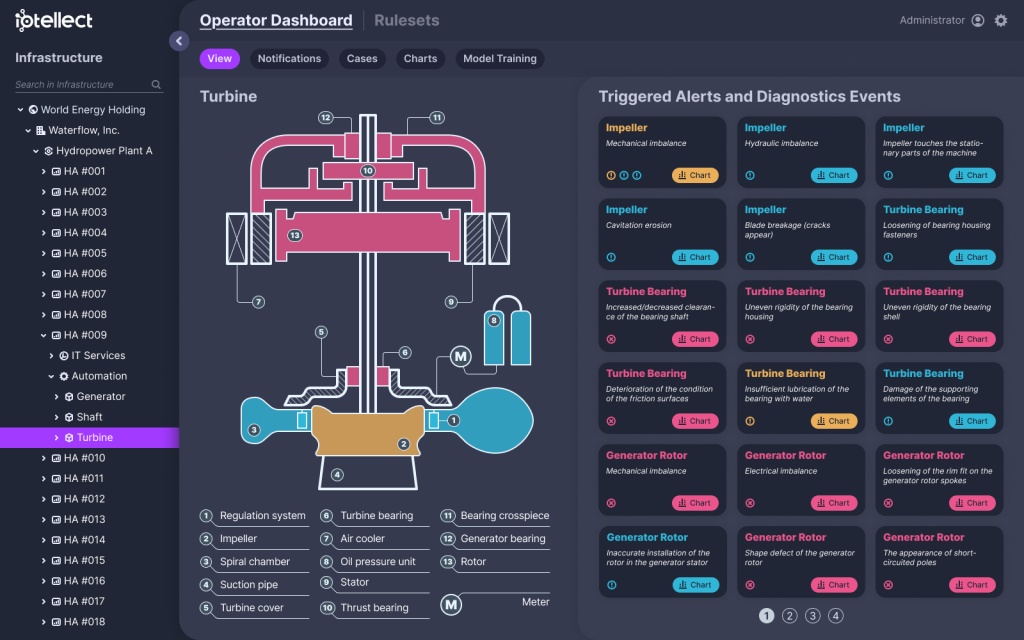

An Automated Predictive Diagnostics System (APDS) has been deployed for industrial operation at a major hydroelectric power station whose identity remains confidential due to NDA. The prototype system is installed on one of the hydroelectric units as part of the client’s strategy to digitize its energy assets.

Powered by the Iotellect platform, APDS leverages advanced predictive models to monitor equipment performance, analyze operating modes, and forecast potential failures at early stages. This proactive approach enables timely maintenance, reduces downtime, and extends equipment lifespan, ensuring stable and efficient energy production.

The Iotellect platform provides the foundation for real-time monitoring and mathematical modeling, making predictive diagnostics more accurate and accessible for large-scale industrial operations.

Hardware and Environment

The project is powered by the Iotellect platform, featuring an integrated mathematical modeling module.

Benefits

- Real-Time Performance Monitoring. Continuous assessment of critical parameters and operating modes, providing instant visibility into equipment health.

- Comprehensive Data Analysis. Tracking over 200 key indicators with real-time comparison against optimal operating standards to quickly identify anomalies.

- Early Fault Detection. Advanced diagnostics detect emerging issues before they escalate, preventing unplanned outages and costly repairs.

- Proactive Maintenance Alerts. Immediate notifications to station personnel allow for swift action, minimizing downtime and extending equipment lifespan.

- Optimized Resource Management. Reduced emergency maintenance and better planning of scheduled repairs cut operational costs and increase efficiency.

- Enhanced Reliability and Safety. Predictive analytics ensure stable operation of the hydroelectric unit, safeguarding energy production and infrastructure integrity.

Testimonials

Leveraging the Iotellect platform for the development of the Automated Predictive Diagnostics System has been a game-changer in optimizing hydropower maintenance. The platform’s powerful mathematical modeling and real-time monitoring capabilities enabled us to create a solution that not only predicts equipment failures at early stages but also streamlines maintenance planning and reduces unplanned downtime. Iotellect’s flexibility and robust data handling allowed us to seamlessly integrate with the hydroelectric power station’s infrastructure, ensuring reliable performance and extended equipment life.

Under NDA

Client Representative